Feldspar Processing

Author: admin Viewed: 1718【Close】

2018-04-16 09:51:06

Feldspar is the most common group of rock-forming minerals found in that part of the earth's crust that is accessible to us. The production of glass, for example, is just about impossible without feldspar, because it contains the requisite alkalis and aluminium.

Feldspar is also used in the production of enamels, glass frits, glazes, abrasives, and welding electrodes.

Special orthoclase feldspar is the natural raw material for the hard porcelain industry. Hard porcelain is characterised by its high electric strength, especially at elevated temperatures. Orthoclase feldspar is also used in electric insulators and in spark plugs.

For the above applications, processed feldspar with the following particle sizes is required:

a) 97% < 45 µm (glazes)

b) 97% < 45 µm (tiles and clinker)

c) 97% < 125 µm (insulators, engineering ceramics)

Major components: CaCO₃, SiO₂

Mohs hardness: 6.0-6.5

Available machines: Jaw Crusher, Ball Mill,Magnetic Separator

Applications: Abrasives, Glass, Ceramics

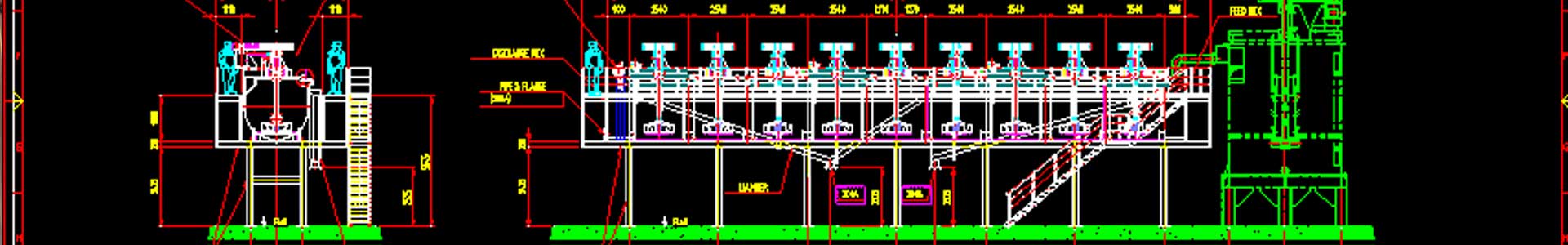

Beneficiation plant for feldspar:

According to the feldspar ore properties, the principle of concentration process is as follows:

1. High quality feldspar manufacturing from the pegmatite: hand picking-broken-grinding (or water-powered roller)-grading.

2. Weathered feldspar of granite: crushing, grinding, classification and flotation (except iron, mica)-flotation (quartz, feldspar separation).

3. Fine grain rock of feldspar (generally contained mica, sometimes contain iron) : crushing, grinding, screening and magnetic separation.

4. Feldspathic sand: Water elution putty-screening (or flotation separation quartz, etc.).