Pebble Processing

Author: admin Viewed: 1781【Close】

2018-04-16 10:52:23

A pebble is a clast of rock with a particle size of 4 to 64 millimetres based on the Krumbein phi scale of sedimentology. Pebbles are generally considered to be larger than granules (2 to 4 millimetres diameter) and smaller than cobbles (64 to 256 millimetres diameter). A rock made predominantly of pebbles is termed a conglomerate. Pebble tools are among the earliest known man-made artifacts, dating from the Palaeolithic period of human history.

Major components: SiO2, Fe2O3

Mohs hardness: 5.0-6.0

Available crusher: Jaw Crusher, Cone Crusher, Impact Crusher

Applications: Cement, Chemical, and Refractory.

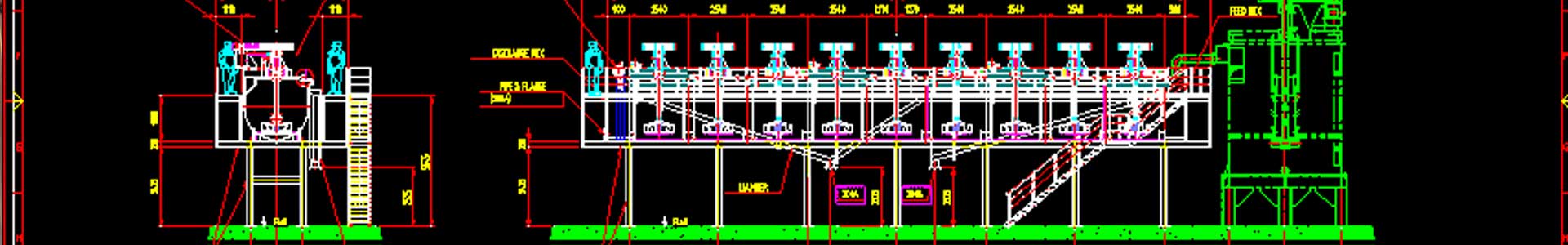

Pebble Crushing Process:

Big stone will be fed into jaw crusher for primary crushing by vibrating feeder. After primary crushing, the material will be transferred to secondary crushing machine like cone crusher for further crushing. Usually, we will equip the pebble crushing & screening plant with multi-deck vibrating screen. Vibrating Screen is a key equipment to sieve the crushed stones into different grades. The crushed stone that meet the demands will be transported to the stockpile, the other will be sent to cone crusher for fineness crushing.