Limonite Ore Processing

Author: admin Viewed: 1736【Close】

2018-04-16 10:36:46

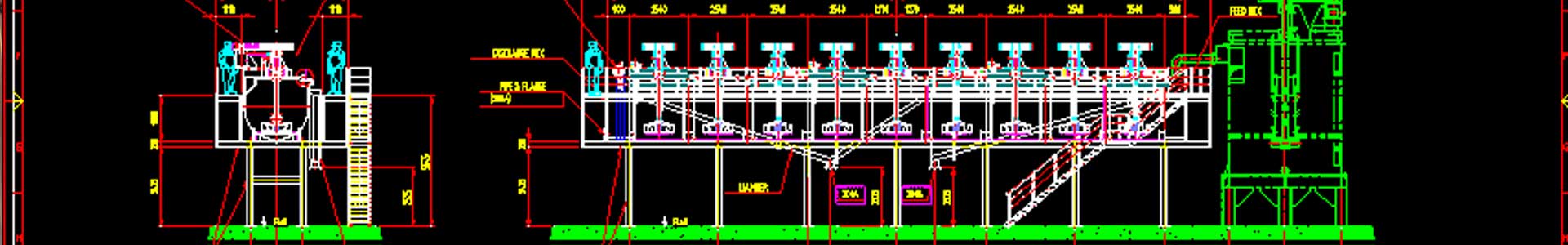

Limonite Processing Equipments & Assorted Production:

The limonite ore processing equipments mainly consist of jaw crusher (rough), vibrating feeder, ball mill, classifier,vibrating screen, shaking table, magnetic separator, and jaw crusher (fine).

1. Single gravity concentration.

Gravity concentration draft is adopted to deal with limonite. In the processing process of limonite, the enrichment of limonite is primarily conducted by spiral chute, and then shaking table is used for concentration to improve the grade of production. Also, centrifuge is often used to separate fine limonite.

Single gravity concentration draft features with simple process, small investment, and quick return. Owing to the relative small capacity of this process, it is often employed in mini-medium processing plant. In addition, shaking table also occupy certain area.

2. Single wet-type and high intensity magnetic separation.

High intensity magnetic separation, which is relatively cheap and simple, is one of the limonite dressing processes. Using the high intensity magnetic separation and assorted equipments of limonite dressing can improve the grade of limonite in large scale. However, the production recovery is not the highest of all processes.

3. Single flotation technique.

Reverse flotation of limonite dressing aims at relative single limonite, also its cost of production is rather high. This technique focuses on solving the influence of small particles of slime.

4. Selective flocculation flotation.

By the help of starch and humic acid salt, etc, the process and assorted equipments of limonite dressing can make the limonite selectively flocculated. And then eliminate silicate mineral through de-sliming or reserve flotation.

5. United process of dressing limonite.

(1) High intensity magnetic separation-direct flotation.

(2) High intensity magnetic separation-reserve flotation.

(3) Magnetic roasting-low intensity magnetic separation.