Gypsum Processing

Author: admin Viewed: 1743【Close】

2018-04-16 10:18:52

Gypsum is also called plaster. The gypsum mine is the main raw material to produce gypsum binder and gypsum building products and the retarder of portland cement. After calcining under 600~800°C and adding little catalyst ( such as lime ), we can levigate the whole mixture and get anhydrite binder which is also called Kim Binder. After calcining under 900~1000°C and levigating, we can get calcined gypsum. We can use both the plasters in the production and the strength is higher than the usual building gypsum products. Plaster of paris has better wear resistance and water resistance.

Major components: CaSO4

Mohs hardness: 2.0

Available crusher: Jaw Crusher, Impact Crusher,Ball Mill

Applications: Mining, Fertilizer, Cement

Gypsum beneficiation and processing methods:

There are two methods in gypsum calcination process. They are dry calcining and wet calcining. Dry calcining is heating the gypsum for dehydration under the ordinary atmospheric pressure (or low water vapor pressure), along with the generate ofβ-hemihydrate gypsum, Ⅱ-type anhydrous gypsum or burnt gypsum. The gypsum, casting gypsum and pre-products gypsum are commonly used in construction. The wet calcining is hearting under the water vapor pressure in the autoclave or in the low pressure, boiling point higher than 100℃ of the salt solution. Then produces α-hemihydrate gypsum, the basis material to cast a special gypsum.

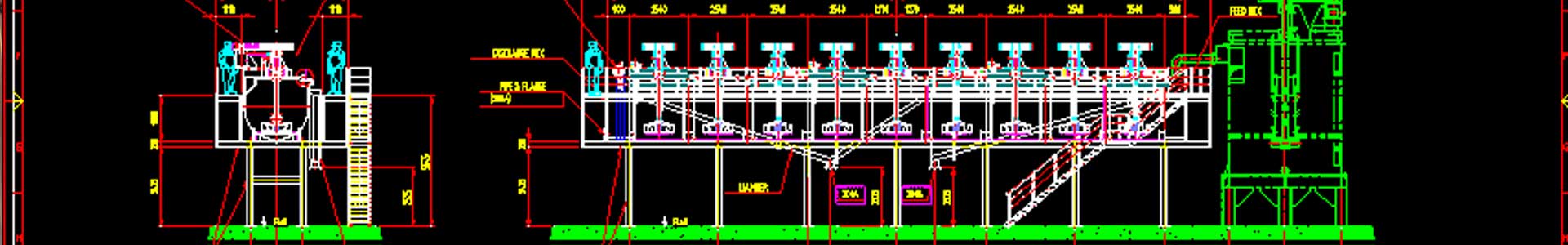

Gypsum process Plant:

β-type gypsum production process generally is: ore storage→crushing →uniform → calcined and dehydrated→aging→grinding and mixture→packaging, first milling then calcination in the calcination process.

Dry calcining gypsum process is: run-of-mind gypsum transported from the stope, then stored and selected to ensure continuously feeding and stable quality. The gypsum are fed into primary crusher(jaw crusher) and is crushed into the diameter shorter than 8cm,and then crushed by the secondary crusher(hammer crusher) become the diameter shorter than 2cm. and then delivered by the bucket elevator to the calcining kiln for calcination. By controlling the temperature of the kiln can separately produce β-hemihydrate gypsum, anhydrite gypsum and burnt gypsum.

α-type gypsum wet calcination process generally is : gypsum raw materials bin→ screening→ autoclaving and drying → grinding → uniform →α&β gypsum mixture →packaging and transporting. Hot water production method processing: run-of-mine ore→crushing→grinding→reacting caldron (water and pharmaceutical) →washing→drying→packaging.

Gypsum beneficiation and processing plant:

Equipment commonly used in gypsum crushing includes jaw crusher, cone crusher, impact crusher, roll crusher, hammer crusher, and so on. The commonly used grinding machines, like ball mill, etc.