Copper Mining Processing

Author: admin Viewed: 908【Close】

2018-04-16 09:46:09

Application: In modern industry and daily life, copper has a wide range of application and demand. It has an important and irreplaceable position in electric, marine, aviation, communication, petrochemicals, household appliances, high-energy physics, metallurgy, etc.

Types of copper ore: Composition of copper ore is very complex, including chalcocite, chalcopyrite, azurite, tetrahedrite, malachite, etc. Different beneficiation process is designed according to different ore. Even if the same type of ore in different mining plant, the beneficiation process is also different. According to the properties of different ore, we will choose suitable beneficiation process.

The beneficiation methods and quality requirements of copper ore:

Flotation is main method of copper ore beneficiation; some are also using with magnetic separation, gravity separation and wet smelting, etc.

To choose the right method of beneficiation, we should study the components and structure of copper ore, and identify the type (natural and industrial) of copper, and know about the content of refractory minerals in the ore and its general distribution, etc.

According to the different proportion of copper oxide and copper sulfide, The natural copper ore can be divided into sulfide ore (containing copper oxide below 10%), mixed ore (containing copper oxide, 10 ~ 30%) and oxidized ore (containing copper oxide more than 30%).The common methods of beneficiation for different types of copper ore, as below:

Beneficiation of single sulfide copper ore:

1.Generally, it adopts flotaion.

2.Beneficiation of polymetallic sulfide ores. Generally, according to the different processing technology of main components and the characteristics, we will adopts mixed flotation, preferred flotation, mixed and preferred flotation, flotation and gravity combined beneficiation, flotation and magnetic separation combined beneficiation, flotation and wet smelting combined method.

3.Mixed ore beneficiation.Generally,we will adopt flotation beneficiation. It can be processed separately, or together with the sulfide ore. And also can adopt flotation and wet smelting combined processing, that is to say, copper concentrate selected firstly by flotation, the tailings after flotation are processed in wet smelting .

4. Oxidation ore beneficiation. Generally, we adopt flotation and wet smelting combined method or separation and flotation combined processing. we adopt wet smelting processing to deal with ore which has large content of cooper oxide.

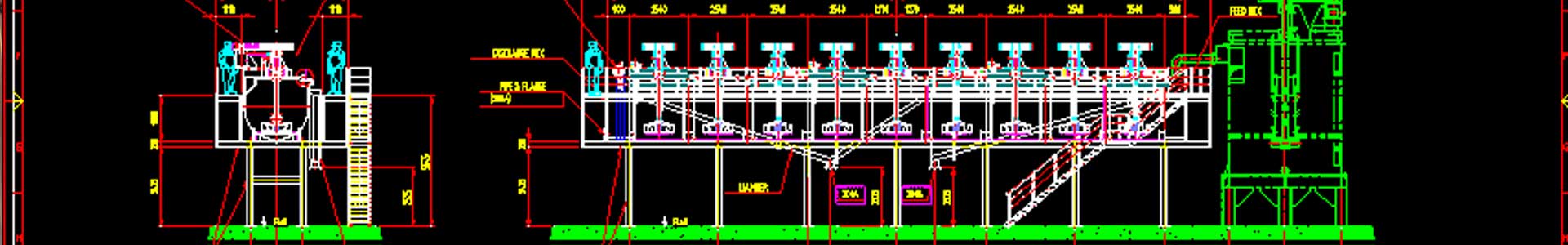

Main equipments of copper processing plant

According to the common beneficiation process,the copper processing plants are generally divided into:crushing – grinding – classifying – flotation – copper concentrate and tailings process.

Crushing equipments: it will adopt tertiary or fourth crushing in the medium and large mining plant.To achieve the modern dressing concept of more broken and less grinding, Many mining plant adopts the crushing and inspecting process. Lipu has nearly 20 years’ manufacturing experience; we can provide many kinds of crushing and grinding equipments.

Grinding equipments: Since 19th century, ball mill is the first choice of grinding equipment.With features of simple structure, strong process controlled, easy maintenance and long life, ball mill is the main equipment of grinding equipment. the capacity of ball mill produced by Lipu can reach 300 - 2500t / d, and meet the basic process requirements of customers.

Classifying equipments: Classifying equipment is professional equipment for inspection process and control of grain size. The common equipments of classifying are spiral classifier, high frequency screen, hydrocyclone, etc.

Flotation equipments: Flotation equipment is a main equipment of chemical flotation, including: floatation column, flotation tank. Flotation tank has many models and volume, the commonly models of flotation machine: SF series, XJK Series, KYF Series, XCF Series, JJF Series and BF Series. they are divided into two types of self-suction and washed gas. The volume can achieve from 0.37 – 32 m³.According to different process, you can choose the right model and volume.At present, Shanghai Lipu flotation machine can meet the needs of different conditions.

About copper concentrate after flotation, it also requires filtering, drying and packaging. These equipments can be chosen according to the scale of mining plant.

There are many forms and methods for tailings process. Before 1970, tailings dam was common used. In recent years, Shanghai Lipu has developed equipment and technics to process tailing discharging with dry way.The process and equipment has been used widely.The promotion and application of new equipmet and technology, has been greatly reducing the investment of dealing with tailings for the investors.