Calcite Processing

Author: admin Viewed: 862【Close】

2018-04-16 09:39:59

Calcite powder is a natural form of calcium carbonate with extremely high whiteness, purity and free flowing in nature. Calcite powder and coated calcite powder has a pivotal role in the modern industrial like plastic, paint, cosmetic, paper, PVC pipe etc. due to its versatility, availability, and traceability.

Major components: CaCO₃

Mohs hardness: 3.0

Available crusher: Cone Crusher,Jaw Crusher,Ball Mill

Applications: Cement,Chemical, and refractory.

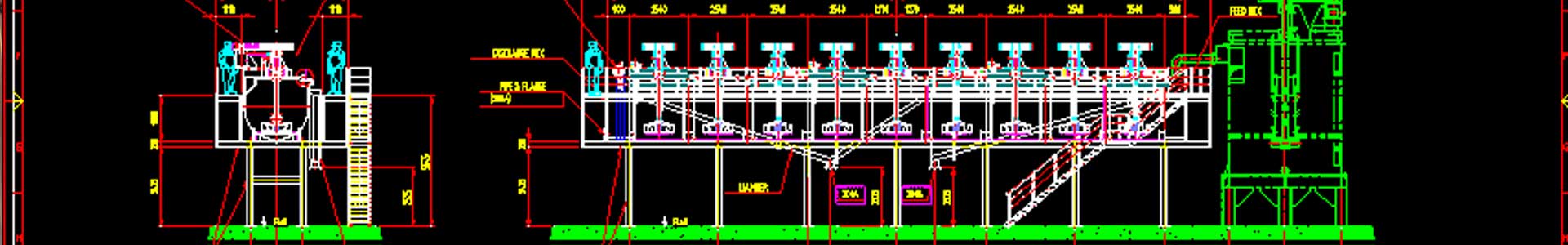

Calcite Processing Plant:

Big calcite materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing. After first crush, the material will transferred to impact crusher by belt conveyor for secondary crush; the crushed calcite materials will then transferred to vibrating screen for separating. After separating, the parts that can meet standard will be transferred away as final products, while the other parts will be returned to impact crusher, thus forming a closed circuit. Size of final products can be combined and graded according to your specific requirement.

Calcite Grinding Process:

Ball Mill is the key machine in calcite grinder plant. Ball mill can be used to grind various ores and other materials and has found its extensive application in the field of mine-selection, building materials and chemicals. And the ball mill can also be divided into two kinds: the dry process and wet process. And according to the different mine discharging types, the ball mill can also be divided into two kinds: grid type and over-flow.

We manufacture and install complete line for obtaining micronised Calcite (CaCO3) from 75 micron till 1 micron according to the request of the customer. Our system is based on dry grinding and classification of particles.