Zinc Ore Dressing

Author: admin Viewed: 1815【Close】

2018-04-16 10:56:24

Usage:

Zinc is a very important kind of non-ferrous metal, the product with this element has a widely usage and a great demand. It can be used as coating of anticorrosive food, automobile manufacturing, mechanical industry, zinc containing gold casting, dry cell, rubber paint, enamel, medicine, printing, fiber, etc.

The kind of zinc ore:

There are so much ore within zinc element, such as sphalerite,rhombohedrons zinc mine, red zinc mine, silicon metal, sphalerite iron, etc. Ens is a point of zinc ore dressing. The density of zinc ore is 3.9-4.1 t/m³, hardness is 3.5-4.0. Because the raw ore is different, the beneficiation process is different, it is not derivative. It is need to make a small beneficiating trial to ensure the reasonability of process. Our China is a country with a big mount of zinc. America, Australia, Canada, Mexico, Peru are main origins of zinc in the worldwide.

The beneficiating ways of zinc ore:

For low grade containing zinc ore, washing is the necessary method, then it became zinc concentrate. The grade of zinc concentrate is 40% at least, and the impurity content is not exceeded the standards of national and metallurgy enterprise. Our undressing zinc ore’s grade is between 1% and 7% generally, some respective ore’s grade is up to 10%. Flotation is the main method for zinc ore dressing. Because of accreting with lead content, copper content and sulfur mineral, different separating ways are used: for metal sulfide ore, traditional way is flotation primary and mixed rough concentrate then separation, that is select lead firstly, then copper zinc separation or zinc silicon separation; for sulfide deposit, the general way is: flotation with selecting lead firstly, then selecting zinc.

For mixed ore like sulfide ore and oxide mineral, the general flotation order is sulfide ore selected and then oxide zinc ore floated adding sodium sulfured as activator.

For the oxide zinc which is difficult to select. First adding the sodium sulfured as activator, and then adding other typical drug to get a better beneficiation effect.

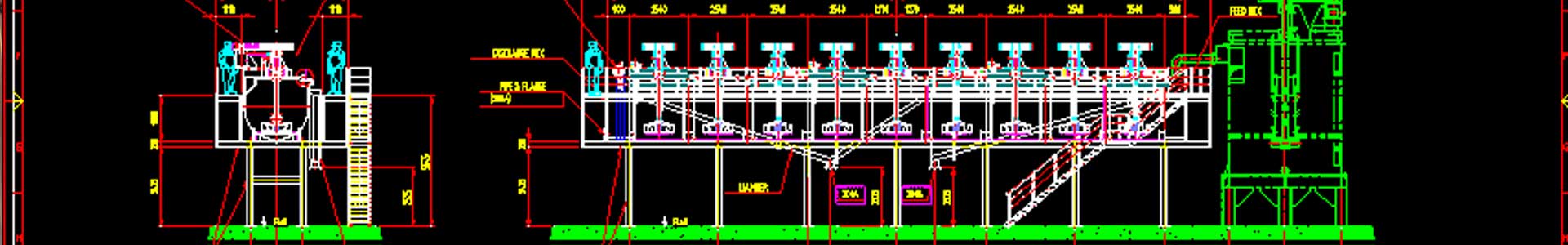

Main Equipments of Zinc Ore Dressing

Crushing Equipment:

For medium scale’s concentrator, general crushing process with Three sections + One closed circuit process. The crushing equipments include Jaw Crusher, Cone Crusher, Circular Vibrating Screen, Belt Conveyor, Vibrating Feeder, etc. the process is in accordance with modern beneficiation method which is more crushing and less grinding. Lipu Heavy Industry has so many years’ manufacturing experience, we can provide all kinds specifications of crushing and screening equipments.

Grinding Equipment:

For decades, Ball Mill is the preferences of grinding equipment. The capacity from 300t/h to2500t/d‘s Ball Mill made by Lipu Heavy Industry, it can meet requires of any process.

Flotation Equipment:

Most concentrator uses Flotation Machine as the main equipment. there are aspirated flotation machine and inflatable flotation machine. The volume is from 0.37m³to 32m³.we can choose corresponding model and volume according to the different processes. From now on, flotation machine made by Lipu Heavy Industry could be used in any kinds of producing.

The zinc concentrate after floating, it also need to concentration, filter, dryer and package. The electrotype of these equipments is made according to the producing scale.