Fluorite Processing

Author: admin Viewed: 989【Close】

2018-04-16 10:05:04

The molecular formula of Fluorite is CaF2, it also named thulium. In modern process, it has very original purpose. Powder fluorite concentrate applies in metallurgy, chemical, machinery and glass industry, etc. massive fluorite concentrate as steelmaking solvent in industry, then slag liquidity increased and impurities like sulphur and phosphorous removed.

The density of fluorite is 3.0-3.2 t/m³, hardness is 4.0, loose density is 1.6 t/m³. Fluorite ore is divided into three types; they are silicate ore deposit, carbonated ore deposit and polymetallic ore deposit.

Main origins of fluorite ore are South Africa, Mexico, China, Canada, etc.

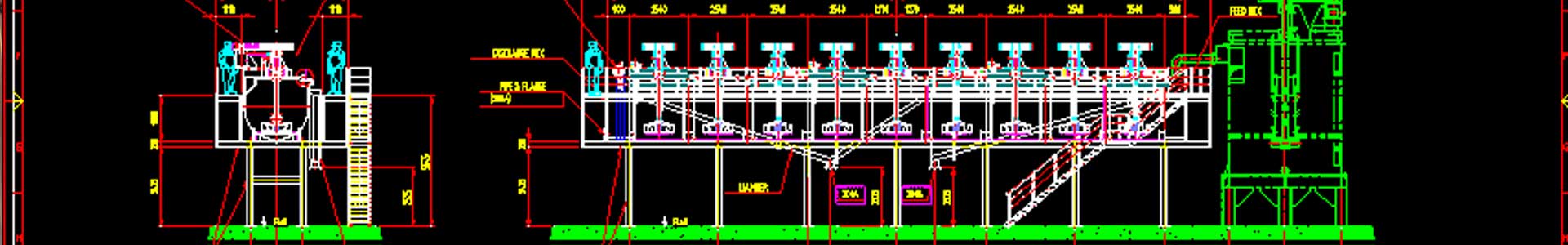

Fluorite beneficiation is divided into two parts. Massive fluorite ore is produced to meet steelmaking needs; manual election method is the main way to separate. Raw ore is divided into several sizing grades by fixed screen and vibrating screen, through manual election respectively, the massive fluorite concentrate is elected out. Another part of fluorite ore is crushed, grinded and floated, and then the powder fluorite concentrate is elected out. The features of its process are: crushing system uses Three sections + One closed circuit or Two sections + One closed circuit process; Periodicity grinding Periodicity separating. Some handpick fluorite concentrate is using more selections process. According to the differences of undressing ore property, a trial should be made to improve the reliability of beneficiation process.

The main equipments include Jaw Crusher, Cone Crusher, Circular Vibrating Screen, Ball Mill, Spiral Classifier, Hydrocyclone, High Frequency Fine Screen, Flotation Machine, Thickener, Filter, Dryer, etc. Lipu Heavy Industry has a great experience of manufacturing these equipments, and they can meet producing requests of different process.

Fluorite concentrate is divided into several degrees, the lowest grade of powder fluorite concentrate is up to 93%, and the lowest grade of massive fluorite concentrate is up to 65%. In addition, the impurity content of SiO₂,S,P,CaCO₃ should be accorded with the standards of National and enterprise.