Hematite Processing

Author: admin Viewed: 975【Close】

2018-04-16 10:23:05

The molecular formula of hematite is Fe2O3; it belongs to weak magnetite iron ore content. It usually accretes with magnetite ore. In China, hematite as a major mineral in quite a number of iron ore. The main origins of iron ore are Australia, Brazil, India, Canada, Russia, etc.

The density of hematite is 4.8-5.3t/m³, hardness is 5.5-6.5, loose density is 2.5-3.0t/m³.

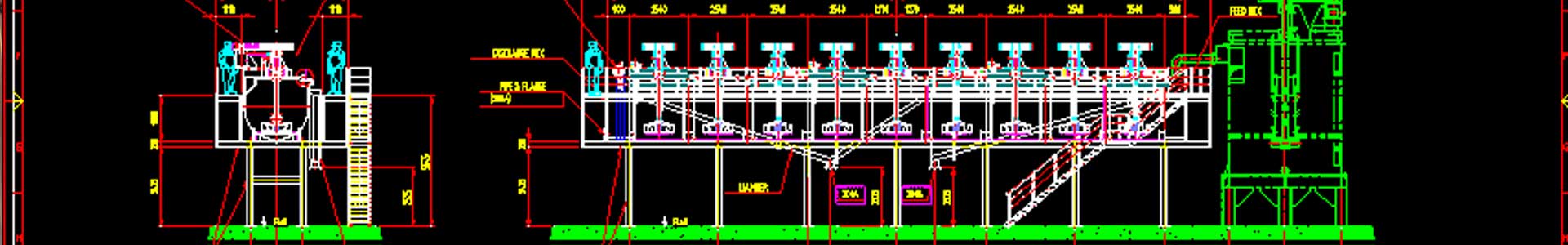

The crushing system of hematite ore uses Three sections + One closed circuit process generally.

After hematite ore crushed, its basic beneficiation process is Periodicity grinding or continuous grinding—weak Magnetic Separator—high gradient strong Magnetic Separator—anion reverse Flotation process. According to the difference of undressing ore grade, embedded cloth degree, gangue minerals composition and undressing ore properties, it can be used Degree Separator. Re-election for coarse grain. If S, P elements are exceeded bit, the Flotation process should be added to impurity. a trial should be made to improve the reliability of beneficiation process.

The main equipments include Jaw Crusher, Cone Crusher, Circular Vibrating Screen, Ball Mill, Spiral Classifier, hydrocyclone or High Frequency Fine Screen, Magnetic Separator, Flotation Machine, Thickener, Filter, Spiral Chute etc. Lipu Heavy Industry has a great experience of this magnetite beneficiation process. We can form varieties of specifications of crushing, screening, grinding and provide varieties of beneficiation equipments.

After beneficiated, the grade of iron concentrate is up to 64% or more, SiO2 amount should be controlled under 6% ( as low as better), the amount of toxic elements like S, P should be achieved the standards of national and iron enterprise.