Lime, Gypsum & Cement Grinding Line

Author: Viewed: 813【Close】

Material: Sulphate-aluminium cement clinker, Portland cement, Metakaolin, Lime, Gypsum, etc

Input Size: <1mm

Moisture: <5%

Application: Anchoring agent production

Equipment: SCM1250 Ultrafine Mill, screw conveyer, powder packaging machine, pneumatic conveyer and so on

Project Overview

From project design to installation &commission

This complete system of the anchoring agent production was produced.With the facilities, the production line was able to realize centralized control, automatic production and troubleshooting during the production process. Besides, the project boasted easy operation, easy learning and use, etc.

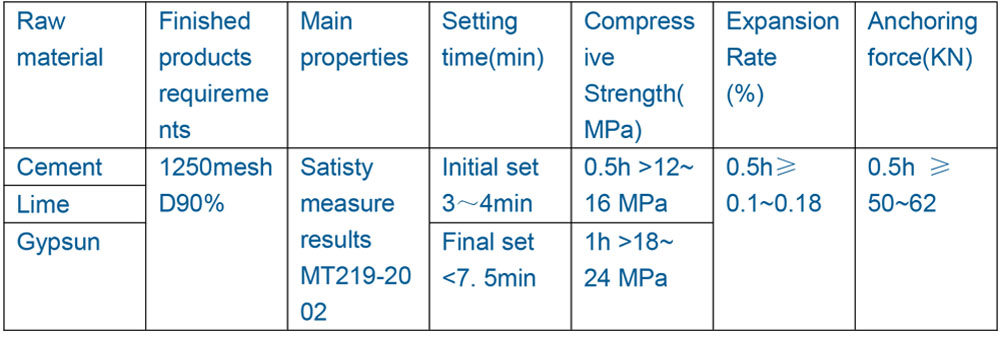

Final Products Requirements

Equipment Configuration

Different from the standard design, this production line was improved according to customers’ requirements. The whole production line mainly contained the SCM1250 ultrafine mill (the main equipment), screw conveyer, powder packaging machine, pneumatic conveyor and so on, which met the requirements of the two sets of production processes of anchoring agent.

Production Process

With the help of PLC and visualized operation, the degree of automation is quite high; Benefiting from the technology, the scheme configuration is very reasonable.

1.The first stage:

Raw material feeding system: The separating stored cement, lime and gypsum and some other raw material of the anchoring agent are fed to the weighting system through the feeding equipment.

2.The second stage:

Weighting system: According to the set ratio, different raw materials are weighted.

3.The third stage:

Stirring system: After the weighting system, the materials are stirred and mixed in the zero-gravity mixer.

4.The fourth stage:

Grinding system: The mixed materials are fed into the ultrafine powder grinder through screw feeder to be ground and classified. As the key process, SCM1250 ultrafine mill grinds the powder until the powder is as fine as 1250 mesh.

5.The fifth stage:

Conveying, storage and packaging system: Finished products are collected by pulse dust collector and sent to tank by the pneumatic conveying system, packed by packaging system and transported.

Equipment Advantages

The main equipment in the anchoring agent production is SCM1250 Ultrafine Mill ---- a high-efficiency but low-cost machine developed by connecting mill production experience and advantages of domestic and overseas mill manufacturing.

1. High Efficiency:

Newly designed grinding roller, grinding ring and grinding curve can promote the grinding efficiency. Under the condition of the same fineness and power, the capacity of this mill is 40% higher than that of jet grinding mill &stirred grinder and more than twice that of ball mill; while the consumption of the system is only 30% that of jet grinding mill.

2. High Fineness:

Both single-head powder separator and multiple-head powder separator are optional. Because the speed of each rotor of the multiple-head powder separator is adjustable, the finished products can be collected directly, without further winnowing, and there is no inferior material. Among the final products, powders smaller than 2μm can reach 70%.

3. Eco-friendly

The use of pulse dust collector, silencer and sound-proof room can remove dust and reduce noise, which is totally in line with the national standards.

4. Low Cost:

The grinding roller and ring are forged by special materials. As a result, the service life is 2-3 times longer than that of impact crusher and turbo crusher under the same condition. And they can be used for 2-5 years when it is used to grind calcium carbonate and calcite.