Pioneer of the 4.0 industry

Author: Viewed: 936【Close】

The 4.0 industry is a high-tech strategic plan proposed by the government of Germany, the corresponding concept in China is "made in China 2025", the Ministry of industry and Chinese Academy of engineering define Chinese version of industry 4.0 core objectives as intelligent manufacturing, this description is very accurate. From intelligent manufacturing and then extends to the specific factory, it's called intelligent plant.Intelligent manufacturing, intelligent plant is the two largest industrial 4.0 goals. Under the influence of industry 4.0, all walks of life are beginning to have intelligent exploration.

Project overview

Solution design - installation and debugging

The customer has an old production running line less than 3 years in basalt crushing site, they adopted other domestic manufacturers of equipment before, while it has general capacity and high maintenance cost, which led to change most main equipment within 3 years. Finally, the customer replace two sets of HST315 single cylinder hydraulic cone crusher, one PE900x1200 jaw crusher in December 2015, now host device HST315 single cylinder hydraulic cone crusher using the current top intelligent control methods in china, after the transformation of installation and debugging nearly a month, it has been put into running about three months. Besides, the production of sand and gravel aggregate size is excellent, it is very popular even if there is a higher price in building materials market, of course, users are very satisfied with Echo 's products and services.

Project background

China to increase investment in infrastructure, which is influenced by "The Belt and Road", "13th Five-Year" plan. "The Belt and Road" along involving the more than 60 countries, infrastructure construction is in the accelerating period, total investment or up to $6 trillion. 2016 China Railway Corporation plans to complete the investment 800 billion yuan. "12th Five-Year" railway fixed assets investment will achieve 3.58 trillion yuan while the new production line of 3.05 million kilometers in operation, compared with "11th Five-Year" growth of 47.3% and 109% respectively. Railway, highway and other infrastructure needs a large number of sand and gravel aggregate, so high quality sand aggregate production has become a craze for many enterprises to invest.

Natural sand mining costs have become more and more high after years of continuous mining, which cause natural sand resources are rapidly reduced, natural sand have been exhausted or nearly exhausted in many areas, however, natural sand are non-renewable resources, some areas make regulations to strictly prohibit the exploitation of natural river sand, in order to maintain the natural landscape, protect dyke dam, protect the ecological balance.

Under the influence of policy and environmental factors, Hebei Shijiazhuang area encourage enterprises to promote mechanism sand production for protecting ecological environment.

Basalt has the advantages of high compressive strength, low crushing value, strong corrosion resistance, good adhesion, etc. It has been recognized as the best material in the construction of highway, railway and airport runway in the world. Not only that, basalt is also quality aggregate of high-rise building or lightweight concrete, this is due to the characteristics of many pores and hard, it can make concrete lighter with the admixture in concrete, besides, firm as well as sound insulation and heat insulation, it is very favored by the major building materials market, which is very strong demand for basalt material, meanwhile basalt investment has a bright prospect.

Equipment configuration

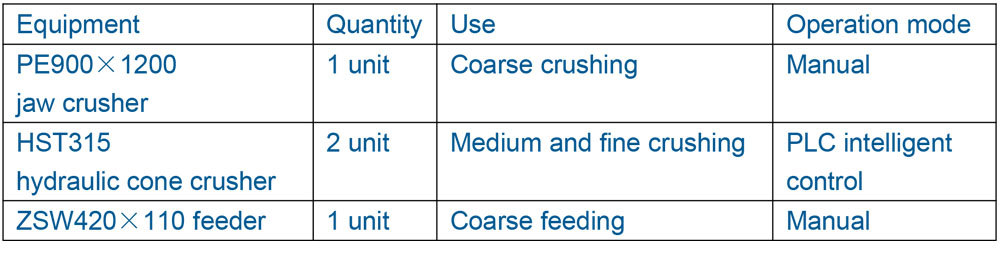

According to the requirements of customers, product material has five kinds after crushing basalt, therefore, among the production line configuration, Echo Equipment engineers replace coarse and fine crushing equipment with low capacity and efficiency according to the original production line equipment situation, at the same time a multi-level product screening, equipped with PLC intelligent control and dust removal system, which ensure entire production line is highly efficient and environmental protection.

The production line including PE900x1200 jaw crusher, two sets of HST315 single cylinder hydraulic cone crusher, one ZSW42x110 vibrating feeders, five sets of 3Y2160 circular vibrating screen, one transfer bin, one dust removal system, along with ten sets of belt conveyor.

Process analysis

20-750mm basalt after separation is given into primary jaw crusher PE900 * 1200 by ZSW420*110 vibrating feeder, then crushing down to 0-300mm is transmitted to transfer bin through belt conveyor. Transfer bin is arranged below the hydraulic valve and small vibrating feeder, first, through the feed and conveyor to two sets of single cylinder hydraulic cone crusher HST315 crushing, second, enter the two sets of 3Y2160 circular vibrating screen and return above 40mm material to transfer bin, last, sieving materials under the product screening of three sets of 3Y2160 circular vibrating screen.

Intelligent control system salute to "industry 4.0": HST315 single cylinder hydraulic cone crusher highlights

The main equipment used by customers is mainstream equipment in currently domestic mine crushing industry ---HST315 single cylinder hydraulic cone crusher, in addition to the equipment advantage of high efficiency, low cost, long service life, intelligent electronic control system has become a major highlight of the production line. Intelligent electronic control system can provide manual control, constant feed control, multi row constant power control mode of operation for users to choose; we can continuous monitor crusher internal actual load and automatic regulating device, so as to optimize the utilization rate of crusher, which make crusher can play best performance at any time; besides, intelligent electronic control system can automatic monitoring and alarm and display various operating parameters, then real-time understand crusher operation. As: it can not continue to use when the lining board wear to replacement period, it will automatically display and alarm in the control panel.

1. central control system: central control system is a special control product that Echo Equipment for large crushing production line or customers with centralized control requirements, the whole system's central control unit is industrial computer, and read the PLC through a variety of communication technology (programmable controller), then collect the status of equipment, furthermore computer sends commands to control the equipment on site according to equipment scene status, so as to realize the remote control of information equipment and equipment record analysis, along with the printer to print out the equipment operation report and other functions. The central control system can realize the automation, intelligence and concentration of the production line, which can meet the requirements of the customers and achieve the decentralized management, centralized control:

1). centralized control equipment, remote control, remote parameter setting.

2).data records, historical inquiry, data printing, boot time recording, automatic storage run time.

3). flexible system, convenient operation, powerful function, share resource, high safety performance.

4). the powerful communication function, the system expansion function, the remote control of the Internet of things, user can view equipment status at any time.

5). high degree of automation equipment operation and fuzzy control. Greatly save labor and material costs.

6). realize the monitoring visualization, production line automation, achieve individual start and stop, a key to start and stop, single control and interlock switch, automatic determination operation fault, automatic stop related equipment in fault condition.

7). rapidly complete the production line upgrade based on the optimization of the production process latter.

2. remote monitoring and control system (IOT): this system allows all devices integrated into network, Wherever we are, customers will be able to view machine's availability as long as there is a device that can access internet, and access to historical records remote monitoring control system, what's more, we can also provide instant warning service, furthermore, when grinding mill is in trouble, we will promptly notify the relevant personnel downtime and provide remote guidance service, it's very convenient without dead angle.